The Future of 3D Printing: Innovations Driving Change

- Bauen Innovations

- Oct 6, 2025

- 3 min read

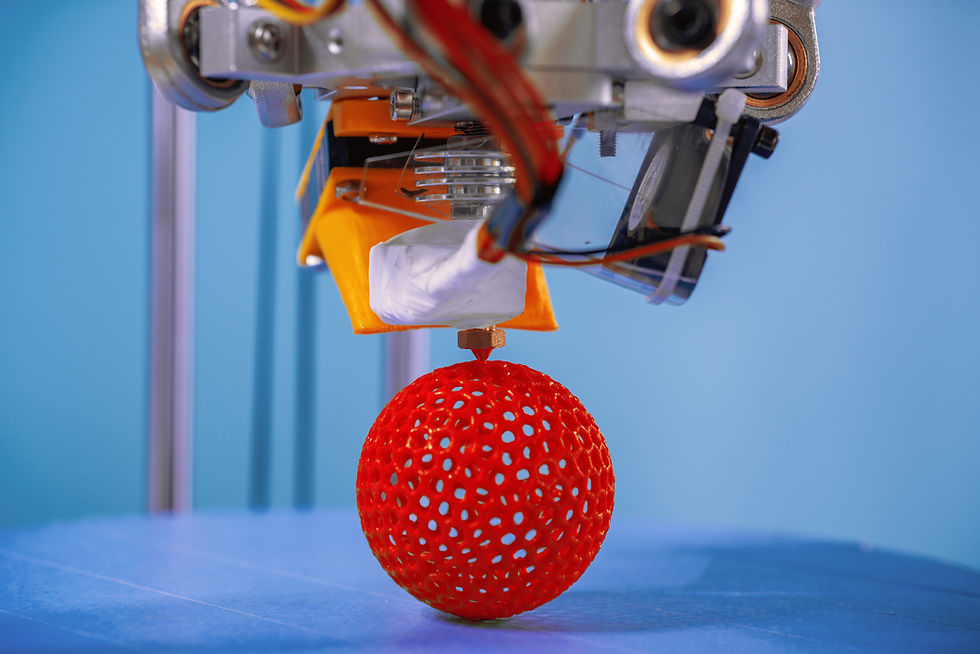

3D printing has transformed from a niche technology into a powerful tool reshaping industries worldwide. Its ability to create complex objects layer by layer offers unprecedented flexibility and customization. As the technology evolves, new innovations are pushing the boundaries of what 3D printing can achieve. This article explores the future of 3D printing, highlighting key advancements and their potential impact.

Emerging Technologies in 3D Printing Innovation

The landscape of 3D printing is rapidly changing due to breakthroughs in materials, hardware, and software. These innovations are making 3D printing faster, more precise, and accessible to a broader range of applications.

Advanced Materials: New materials such as bio-inks, metal alloys, and composites are expanding the possibilities of 3D printing. For example, biocompatible materials enable printing of tissues and organs, while high-strength metals are used in aerospace and automotive parts.

Multi-Material Printing: Printers capable of using multiple materials simultaneously allow for the creation of complex objects with varied properties, such as flexible joints combined with rigid structures.

Speed and Scale Improvements: Innovations like continuous liquid interface production (CLIP) and large-format printers are reducing production times and enabling the manufacture of bigger objects.

These advancements are not only improving product quality but also reducing costs, making 3D printing a viable option for mass production.

The Role of Software and AI in 3D Printing Innovation

Software plays a crucial role in optimizing 3D printing processes. Recent developments in AI and machine learning are enhancing design, error detection, and process control.

Generative Design: AI algorithms can generate optimized designs based on specific constraints like weight, strength, and material usage. This leads to innovative structures that are often impossible to create with traditional methods.

Real-Time Monitoring: Machine learning models analyze data from sensors during printing to detect defects early and adjust parameters automatically, improving reliability.

Simulation and Testing: Advanced software simulates how printed parts will perform under stress, reducing the need for physical prototypes and speeding up development cycles.

These software-driven improvements are critical for industries requiring high precision and reliability, such as healthcare and aerospace.

Who Innovated 3D Printing?

The origins of 3D printing trace back to the early 1980s. Chuck Hull is credited with inventing stereolithography (SLA) in 1983, a process that uses ultraviolet light to cure liquid resin layer by layer. This breakthrough laid the foundation for modern 3D printing.

Since then, many companies and researchers have contributed to the technology’s evolution:

SLS and FDM Technologies: Selective Laser Sintering (SLS) and Fused Deposition Modeling (FDM) were developed in the late 1980s and early 1990s, expanding material options and applications.

Open-Source Movement: The RepRap project, launched in 2005, democratized 3D printing by creating affordable, self-replicating printers, fueling widespread adoption.

Corporate Innovations: Companies like Stratasys, 3D Systems, and newer startups continue to push the envelope with proprietary technologies and materials.

Understanding the history of 3D printing helps appreciate the collaborative nature of its ongoing innovation.

Practical Applications Shaping the Future

3D printing is no longer limited to prototyping. It is now integral to manufacturing, healthcare, construction, and even food production.

Healthcare: Customized implants, prosthetics, and surgical models improve patient outcomes. Bioprinting is advancing toward printing functional tissues and organs.

Aerospace and Automotive: Lightweight, complex parts reduce fuel consumption and improve performance. On-demand printing of spare parts cuts inventory costs.

Construction: Large-scale 3D printers build houses and infrastructure faster and with less waste.

Consumer Goods: Personalized products like footwear, eyewear, and jewelry are becoming mainstream.

Businesses looking to leverage 3D printing should focus on identifying areas where customization, speed, or complexity add value.

Preparing for the Next Wave of 3D Printing Innovation

To stay ahead, companies and individuals must embrace continuous learning and experimentation. Here are actionable recommendations:

Invest in Training: Understanding the latest 3D printing technologies and software is essential.

Collaborate with Experts: Partner with innovators and research institutions to access cutting-edge developments.

Pilot New Materials and Processes: Experiment with emerging materials and printing techniques to discover new applications.

Integrate Digital Workflows: Use AI-driven design and monitoring tools to optimize production.

Focus on Sustainability: Explore eco-friendly materials and energy-efficient printers to reduce environmental impact.

By adopting these strategies, organizations can harness the full potential of 3D printing innovation.

.png)

Comments