3D Printing Services

3D PRINTING SERVICES

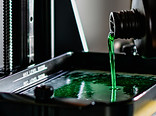

We specialize in FDM and SLA 3D printing, offering custom solutions for everything from individual orders , small and medium-batch productions and prototype creation.

✅ Original files only.

For quality and IP reasons, we only print original and custom designed files

Explore this Page

Full Spectrum 3D Printing Services

File Preparation & Repair

We ensure every model is print-ready — cleaned, scaled, and optimized for accuracy, strength, and flawless production.

Material Selection & Optimization

We match every job to the right material — balancing strength, flexibility, finish, and cost for the part’s real-world use.

Production

Our high-performance printers deliver consistent, repeatable results — from one-off prototypes to full production runs.

Post-Processing & Finishing

Parts are refined, sanded, painted, polished, or assembled to meet aesthetic and functional standards.

Quality Control & Dimensional Verification

Every part is measured and inspected for dimensional accuracy and surface integrity before leaving our shop.

Packing & Shipping

Each order is protected, labeled, and tracked for safe, professional delivery anywhere in the country.

Documentation & Traceability

We maintain revision-locked files, material certs, and inspection data — ensuring every build is verifiable and repeatable.

Why 3D Print With Bauen?

Engineered 3D Printing Expertise

Precision isn’t a feature—it’s a mindset. We treat every project as a problem to be understood, not just produced, balancing physics, materials, and design intent until form and function align.

03

Strong SOP's

Our standards remove uncertainty. Every print follows a defined path — from intake to inspection — refined through hundreds of successful jobs.

02

Experienced team

Our team’s been through every kind of print challenge there is. We know what works, what fails, and why. That experience shows in every job we take — solid, clean, and done right because we take pride in doing it right.

04

Craftsmanship

We care about how things look, feel, and fit. Every surface, edge, and detail matters because our name’s on it. Pride isn’t a talking point here — it’s how we work.

Engineering Grade Materials.

Professional-Grade Results.

Filament Type | Use Case |

|---|---|

PLA | Simple prototypes and display models. |

PETG | Strong and water-resistant, ideal for mechanical parts. |

PETG-CF | Carbon fiber–reinforced PETG; stiffer and more dimensionally stable—ideal for precise fixtures and low-flex functional parts. |

PETG-GF | Glass fiber–reinforced PETG; adds toughness and higher heat resistance—great for parts under load, stress, or moderate vibration. |

ABS | Heat-resistant and moderately tough; suited for DIY enclosures, printed housings, and impact-resistant visual models. |

ABS-GF | Glass-filled ABS; stronger and more rigid than standard ABS—ideal for mounts or covers in vibrating or stress-prone environments. |

PLA | Affordable and easy to print; best suited for visual models, drafts, and basic non-functional prints. |

PLA-CF | Carbon fiber–reinforced PLA that hides layer lines—ideal for high-detail visual models where surface appearance matters. |

TPU | Flexible, rubber‑like, wear‑resistant

|

ASA | UV- and weather-resistant; best for outdoor applications. |

ASA-CF | Carbon fiber–reinforced ASA; stiffer and more dimensionally stable—great for precise outdoor parts needing strength and minimal warping. |

ASA Aero | Lightweight and UV-resistant; used for drone parts, RC aircraft, and flight components where reduced weight and outdoor durability are critical. |

PA6-GF | Glass fiber–reinforced nylon for rugged parts like tool housings, machine covers, or mounts exposed to impact, vibration, or stress. |

PA6-CF | Carbon fiber–reinforced nylon for precision parts like robotic arms, sensor brackets, or UAV frames where rigidity and heat resistance are critical. |

PAHT-CF | High-temp carbon fiber nylon; ideal for strong, heat-resistant tooling and jigs. |

PC | Polycarbonate; Extremely tough and heat-resistant; used for load-bearing mechanical components. |

PC-FR | Flame-retardant polycarbonate; used in electrical enclosures and fire safety-critical parts. |

11650

Hours of print time in 2024

40

Jobs completed in 2024

3100

Rolls of filament in 2024

1750

KG of resin used in 2024

CLIENT WORK

Every part shown here was printed directly from customer-supplied CAD data—with only minor adjustments made to optimize for 3D printing. s These jobs showcase our ability to handle complex geometries, tight tolerances, and advanced materials across FDM and resin systems.

Sensor Holders

Mass 3D Printing of sensor holders to be used to environmental control within a Data Center.

A Look Into Our World of 3D Printing...

.jpg)

.png)

.png)